START THE CONVERSATION NOW AT (313)581-3444

Machinists Since 1928

We've been manufacturing professionals for nearly 100 years.

Our versatile manufacturing capabilities include over 30 CNC machines, an in-house tool room, superfinishing services, vast secondary operations abilities, complete customer inventory & material handling services, all with ISO9001:2015 certified quality control procedures.

CNC Milling

Our Vertical CNC machining centers range from small & blazing fast Fanuc Robodrills, to rigid & powerful 50 taper 60″ x 30″ travel boxway machines. Our Horizontal Machining centers bring more versatility with true 4 axis machining, multiple pallets, travels of up to 35″ x 32″ x 38″ and tooling capacities of up to 132.

All of our CNC machining centers have Renishaw probing systems, reliable Fanuc controls and the ability to have 4th or even 5th axis positional indexing units installed as needed.

CNC Turning

We have nearly 20 CNC turning centers with extreme versatility. We have barfeed capacities of up to 3″ and maximum chucking diameters of 25″. We have everything from sub-spindle, live tooled, dual turret, Y axis, lathes to more traditional 6″ to 15″ chuck lathes with tailstocks. Our twin spindle gantry loading lathe includes live tooling, dual on machine inspection probes and with an autoloading raw stock capacity of 6.75″ in diameter.

ISO 9001:2015 certified.

From First Article Reports to PPAP. We’ve got you covered. Our quality system requires verification through every step of the process. All of our certified calibration equipment is traceable back to national standards. We have a climate control inspection room which houses our fully programmable 5 axis coordinate measuring machine and our master gage sets. We have digital Mitutoyo calipers of up to 60″ and micrometer of over 30″.

Tooling Sales & Distribution

For nearly 40 years we’ve been a distributor for many major brands of cutting tools and inspection equipment. You will be surprised to find we can offer lower prices than most distributors. We can do this simply because we don’t require the mark ups from tooling sales as our sole source of income. Being a distributor benefits our machining operations. Our sales of these products help us keep our distributor status, and that’s how we benefit.

We have distributor status for the following brands:

Mitutoyo, Iscar, Kennametal, Lyndex, Yuasa, Chick, N-Forcer, and Sterling Saw Blades.

Call or email us with the company name and part number for pricing.

Complete Inventory Management

L.A. Martin Company offers a convenient inventory solution by storing items until they are required by the customer. The most advantageous aspect of this service is that customers are billed only when the products are shipped. This inventory management strategy enables clients to benefit from economies of scale without having to bear the immediate financial risk associated with large production runs. This service also ensures a prompt delivery, with available same-day shipping and delivery options.

Secondary Operations

We are dedicated to serving as an all-in-one supplier. Beyond CNC machining, we can deliver parts complete with all specified secondary operations. Our in house secondary operation include: Laser Marking, Broaching, Grinding, Honing, Tumbling, Assembly, Washing, Welding, and Diameter Superfinishing.

To enhance our in-house services, we’ve built a network of trusted vendors to meet your additional processing needs. Some of the more common operations we source include: Heat Treating, Plating, Painting, Sheet Metal Forming, Metal Forging & Casting, and Polyurethane & Rubber Castings.

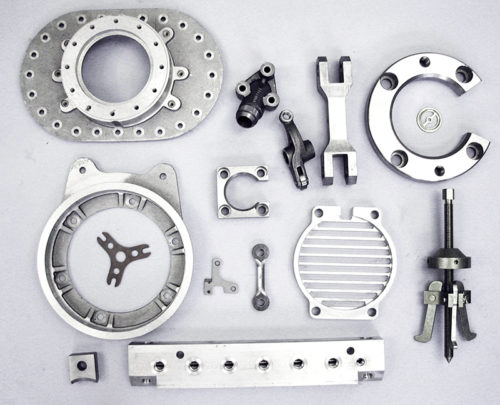

See Our Work

We maintain strict quality standards through all phases of production